Utility Production

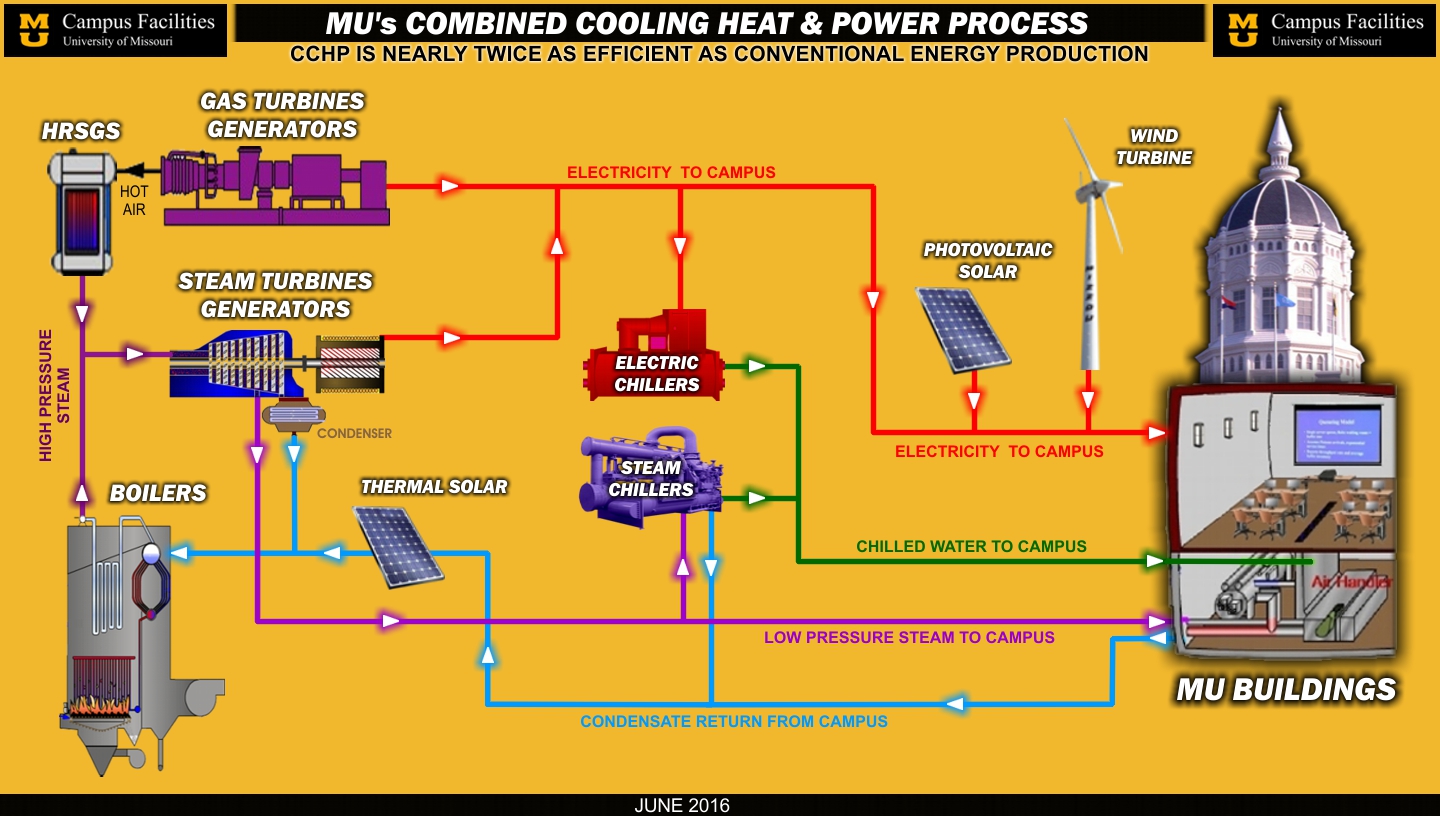

MU’s production facilities operate around the clock to provide the campus with highly reliable and cost-effective utilities essential for campus operation. These facilities incorporate efficient combined cooling, heat and power

Steam

Steam is produced in boilers with technologies comprising of stoker boilers, bubbling fluidized-bed boiler and gas/oil fired boiler. Additional steam is produced by capturing the exhaust heat of the gas-turbine generators using heat recovery steam generators. Sustainable biomass and natural gas make up the majority of MU’s fuel supply. The plant’s fuel flexibility helps provide reliability and cost effectiveness. Up to 1.1 million pounds of steam can be produced for campus thermal needs and electricity production. Steam passes through the turbine generators to co-generate electricity before being sent to campus. Campus steam is distributed through 29 miles of underground steam and condensate return piping system. Steam is used for more than heating. It is also used for sterilization, production of chilled water, cleaning, humidification and other thermal-energy uses.

Electricity

Electricity is produced in steam turbine generators and gas turbine generators. After producing electricity, low pressure steam is extracted from the steam turbines to distribute to the campus. Combined heat and power systems allow the plant to produce a significant portion of campus electricity at nearly twice the efficiency of a conventional power plant.

Up to 66 MW of electricity generating capacity is available and backed with a 40 MW transmission interconnection. MU purchases about one-third its electricity annually through the Mid-Continent Independent System Operator (MISO) when economically feasible. Electricity is distributed to campus through 31 miles of 13.8 kV lines. These power lines run through underground duct banks to a network of switches and building transformers. Looping is used to enhance the reliability especially for critical facilities like the University Hospital, the MU Research Reactor, data/telecommunication centers, and other vital research buildings.

Chilled Water

The campus district cooling system produces and distributes chilled water to air condition campus buildings and provide process cooling for research. The system has 32,000 tons of cooling capacity with about a third of the chillers powered by steam. This same steam is used to produce electricity before making chilled water as part of the highly efficient CCHP process. Various satellite chiller plants, strategically located throughout campus, are connected together by 23 miles of underground chilled water piping. Chillers are controlled and metered centrally by a process control system which optimizes the campus cooling load by operating the most efficient chillers first, reducing the energy to cool the campus.

Water Production

Five water well pumping stations across campus pump water from deep underground aquifers to water storage reservoirs. Following disinfection the water is pumped through a 25 mile piping system to campus buildings. MU's water supply meets all applicable federal and state requirements for a public drinking water system and is tested regularly. Click link to view the most recent Consumer Confidence Report.

Utility Metering and Mapping

All utilities are metered at campus buildings. Energy consumption data is automatically collected and transmitted back to Energy Management for accuracy verification, funding allocation, and to identify potential energy conservation improvements.

A state-of-the-art Geographical Information Systems (GIS) and Global Positioning Systems (GPS) provide accurate utility data detailing locations of 10 different underground campus utility systems, totaling over 200 miles of underground lines/pipes and over 15,000 pieces of equipment. By integrating maps, drawings, databases, images, video and documents, the GIS provides the necessary information to various users for providing safe, reliable and cost-effective utility service to MU.